Qingyuan Automobile Repair Paint Manufacturer Tells You the Prevention and Treatment Methods of Dust During the Automotive Painting Process

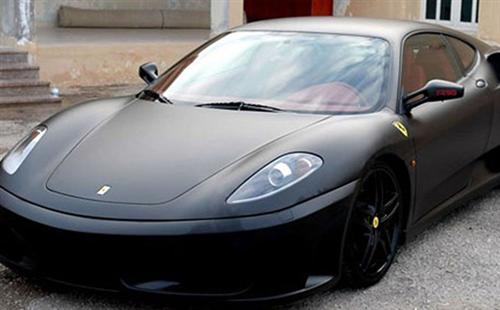

The surface of a car body is generally dazzling and radiant. Generally, the gloss is required to be greater than 90, and the better one can reach around 95, almost resembling the mirror effect. Such a shiny surface will show a clear view of any defects, especially the gray particles, which are very prominent. Grey particles are ubiquitous and impenetrable.

During the polishing process of car body painting and painting, dust particles will continue to occur, making them a major enemy in the high-quality painting process and a difficult to protect enemy. In order to avoid dust particles during the coating process, major automobile factories have almost exhausted all means and tried various methods to reduce the damage of dust particles, improve surface quality, reduce rework rates, and save costs.

1、 Damage of ash particles

On the paint surface of the car body, there are several prominent gray particles that will have a very negative impact on the surface quality and leave a poor front image for customers. If the ash particles are on the surface of the paint and the particle size is not large, they can still be treated by polishing or polishing before submission, otherwise they can only be reworked. The rework rate set by foreign automobile factories is 25, including complete vehicle rework and partial rework.

The rework rate of export vehicles is around 50%, and each rework of a vehicle requires an additional consumption of about 8 kg of paint. In addition, it wastes time and power, and the waste of manpower and material resources is very considerable. Generally, reworking a car requires a waste of 600 yuan of coating materials, with labor, power, etc. totaling over 1000 yuan. Some parts factories that match the entire vehicle have higher rework rates. A certain bumper factory, due to excessive ash particles, has a one-time submission qualification rate of less than 10, and after polishing and polishing, it is also less than 40; This has brought great difficulties to the supply of supporting equipment, and the economic losses are also significant. In order to control the quality of the entire vehicle, large automobile factories have a process called audit inspection, which is called vehicle quality scoring in Germany. The general paint audit quality standard is 70-80 points, and 10 points will be deducted for each gray particle. Grinding marks and polishing shadows also require deduction of points. The gray particles on the surface of electrophoresis and intermediate coating are removed by polishing. If there are fewer gray particles, the polishing operation is naturally less, and the chances of forming polishing marks are greatly reduced. The gray particles on the surface of the topcoat are polished with 2-3 000 grit sandpaper and then polished. If there are fewer ash particles, the consumption of sandpaper, polishing paste, wool balls, etc. will also be reduced, which can save manpower and material resources. Moreover, the chance of deduction for the overall quality score caused by the formation of polishing marks will also decrease.

2、 Monitoring of ash particles

In order to understand the degree of influence of ash particles on coatings, large automobile factories have dedicated personnel to monitor ash particles, including visual counting of ash particles on the surface of vehicle bodies and sampling analysis of ash particles. Some factories even have 2-3 people dedicated to this task, indicating their level of attention. The visual counting of gray particles on the surface of the car body is based on the electrophoresis, intermediate coating, and topcoat of the car body. Five cars of each type are taken daily and counted separately to understand their rules. Some factories also count the ash particles in the interior of the car body. Generally speaking, there may be 30-50 gray particles on the surface of the car body after electrophoresis; 8-20 capsules after intermediate coating; After the topcoat, take about 4-8 capsules.

Article source: Qingyuan Automotive Repair Paint http://www.jinliangxincai.com/

-

08-25

Common problems with automotive repair paint

Why are the orange lines on the surface of the varnish so heavy after each spray? Why on earth? How can we prevent a decrease?Answer: The thinness of the varnish, the amount of paint produced by the s

-

06-05

The car repair paint manufacturer told you about the problem with water-based coatings

1. How long does it take for a skilled paint coating technician to master the operation of water paint?Generally, practice and understanding with less than half a sound can be mastered, and proficienc

-

05-31

Qingyuan Automobile Repair Paint Company tells you the steps for painting

Automotive Painting Process(1) Rust prevention and internal painting of the vehicle body: Depending on the condition of the vehicle body, it will be completed by a sheet metal worker.(2) Polishing and

-

05-12

Why does car repair paint lack luster?

If there is a lack of gloss on the surface of the originally flat and smooth car paint surface, especially during the process of car paint care, it can be observed under a microscope that the surface